In the realm of modern optical communication, ADSS fiber cable, short for All – Dielectric Self – Supporting fiber cable, has emerged as a crucial component, especially for outdoor applications.

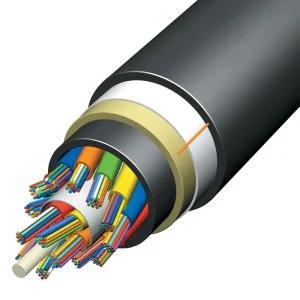

Structure of ADSS Fiber Cable

ADSS fiber cables, renowned for their suitability in diverse outdoor environments, typically come in two main structural designs that are meticulously engineered to balance functionality, durability, and cost – effectiveness. These designs have been developed over time to meet the varying demands of different installation scenarios, from spanning long distances across power grids to connecting remote telecommunication nodes in challenging terrains. Each structure incorporates specific materials and construction techniques, tailored to optimize performance under different conditions, ensuring reliable optical signal transmission while withstanding harsh environmental factors such as extreme weather, mechanical stress, and electrical interference.

Central Tube Structure

In this configuration, the optical fibers are housed within a PBT (Polybutylene Terephthalate) tube filled with water – blocking ointment. This setup ensures protection against moisture ingress. To meet the required tensile strength, a layer of spun yarn, often aramid yarn, is wrapped around the tube. Finally, a sheath is extruded over the assembly. For electric fields up to 110 kV, a PE (Polyethylene) sheath is commonly used, while for higher electric fields (≥ 100 kV), an AT (Anti – Tracking) sheath is employed. This structure offers advantages such as a small diameter, which results in a lighter – weight cable. It also has good waterproof performance and is relatively inexpensive. Installation is straightforward, but the fiber length available within this structure is somewhat limited.

Layered Twist (Stranded) Structure

Here, optical fibers and water – blocking grease are inserted into individual optical fiber loose tubes. These loose tubes are then wound around a central reinforcement, usually made of FRP (Fiberglass – Reinforced Plastic). Similar to the central – tube structure, aramid yarn is wrapped around the assembly for strength, and a PE or AT sheath is extruded. Depending on the environmental conditions of cable installation, single – layer or double – layer sheaths can be used. The single – jacket ADSS – S cable, with a single layer of protective polyethylene, is suitable for short – to – medium – span applications, providing basic protection against environmental factors like moisture, UV radiation, and temperature variations. The double – jacket ADSS – D cable, on the other hand, offers enhanced protection against mechanical stresses such as tension and compression, making it more suitable for long – span applications. The stranded structure allows for more laying methods, including overhead, direct – buried, pipeline, and underwater installations. It also enables better control of fiber core lengths and can accommodate a larger number of fiber cores, though it comes at a higher cost.

Working Principle

ADSS fiber cables operate on the basic principle of optical fiber communication. Light signals are transmitted through the glass – fiber cores within the cable. The all – dielectric nature of the cable means it can be installed in close proximity to high – voltage power lines without the risk of electrical conduction. The self – supporting feature is due to the reinforcing members, such as aramid yarn, which are strong enough to bear the cable’s own weight and withstand external loads like wind and ice. This allows the cable to be suspended directly from utility poles or power line structures, eliminating the need for additional support wires in many cases.

ADSS fiber cables are extensively used in the power sector. They are installed along power pole frames, both for new installations and retrofitting existing power lines. In power distribution networks, especially in urban and rural areas, ADSS cables are used to establish communication links between substations, distribution centers, and remote monitoring points. This enables real – time monitoring of power grid operations, such as load levels, equipment status, and fault detection. For example, in a large – scale wind farm, ADSS cables can be used to transmit data from individual wind turbines to the central control station, ensuring smooth operation and maintenance of the wind power generation system.

Telecommunications

In the telecommunications industry, ADSS fiber cables play a vital role in providing high – speed broadband connections in remote or hard – to – reach areas. When laying fiber – optic networks in mountainous regions or areas with limited infrastructure, the self – supporting and lightweight nature of ADSS cables makes them an ideal choice. They can be quickly installed along existing utility poles, reducing the need for extensive civil works. This helps in expanding the coverage of high – speed internet and voice services, bridging the digital divide between urban and rural areas.

ADSS fiber cables find applications in the transportation industry as well. For instance, in railway systems, they can be used to connect signaling systems, security cameras, and communication devices along the tracks. This ensures seamless communication and real – time data transfer for efficient train operation and safety management. In toll road systems, ADSS cables can be used to transmit data from toll booths to the central management system, enabling smooth toll collection and traffic monitoring.

Optic Fiber Core Loose Tube Outdoor Fibra Adss Fiber Optical cable

Adss Fiber Optical cable Can be installed without turning off the power

Light weight and small diameter reduce loads due to ice and wind and loads to towers and reverse struts

Good tensile strength and temperature properties

Lifespan is 30 years

View Product